Electromagnetic Compatibility Principles and Design

A short course presented on-site at Schneider Electric

April 1-3, 2025

This course reviews fundamental concepts and design strategies that engineers can utilize to ensure their products meet electromagnetic compatibility requirements the first time they are tested and at the lowest possible cost.

The information on this page is for Schneider Electric employees attending the training seminar above. The page will be available until May 3, 2025.

Course Slides

The course slides can be downloaded here.

Supplementary Notes

The EMC Course Notes downloadable in the links below have additional information related to topics covered in this course.

Course Description

This 3-day course provides an overview of electromagnetic compatibility (EMC) requirements and design considerations.

Course Outline

Day 1 - Important Fundamental Concepts

- Introduction

- Overview of Electromagnetic Compatibility

- Coupling Mechanisms

- Analog, Digital and Power Circuits

- Circuit Components and Parasitics

- Resistance, Capacitance and Inductance

- Absolute, Self, and Mutual Capacitance

- Self, Mutual and Partial Inductance

- Component Parasitics

- Estimating Parasitic Values

- Signal Routing and Termination

- Tracing Current Paths

- Transition Time Control

- RLC Circuits

- Transmission Lines

- Identifying the Unintentional Antennas

- Essential Elements of an Antenna

- What Makes a Good Antenna?

- What Makes a Poor Antenna?

- Noise Sources and Coupling Mechanisms

- Integrated Circuits as Sources of EMI

- Parasitic Oscillations and Unexpected Sources

- Coupling Between Noise Sources and Antennas

- Differential Mode to Common Mode Conversion

- Grounding

- Definition of Ground

- EMC Ground vs. Current Return

- EMC Ground vs. Safety Ground

- Ground Structures and Grounding Conductors

- "Ground" in Mixed Signal Environments

- Analog and Digital Components on a PCB

- Power Ground

- Ground in Circuit Simulations

Day 2 - Essential EMC Design Concepts

- Filtering

- Insertion Loss

- First-Order Low-Pass Filters

- Second-Order Low-Pass Filters

- Components Parasitics

- PCB Filter Layout

- Transient Protection

- TVS Diodes and MOVs

- Thyristors and GDTs

- When to Use It

- How to Connect It

- EM Shielding

- Electric Field Shielding

- Magnetic Field Shielding

- Shielding Enclosures

- Cable Shielding

- DC Power Distribution and Decoupling

- Effective Power Distribution Strategies

- Choosing and Locating Decoupling Capacitors

- Low-Inductance Capacitor Connections

- DC Power Distribution and Decoupling

- Effective Power Distribution Strategies

- Choosing and Locating Decoupling Capacitors

- Low-Inductance Capacitor Connections

- Power Electronics Design for EMC

- Board Layout of Power Electronics Circuits

- Filtering to Control Conducted Emissions

- Component Selection and Placement

Day 3 - EMC Design Strategies

- Key System-Level Design Considerations

- For Radiated Emissions Tests

- For Conducted Emissions tests

- For Radiated Immunity Tests

- For Electrical Fast Transient Tests

- For Lightning Surge Tests

- For Electrostatic Discharge Tests

- An EMC Compliance Strategy

- Reviewing a System Design

- Reviewing a Board Design

- Identifying Grounds, Current Paths and Antennas

- Recognizing Safety Critical EMC Issues

- Performing a Worst-Case Analysis

- Specific Design Examples

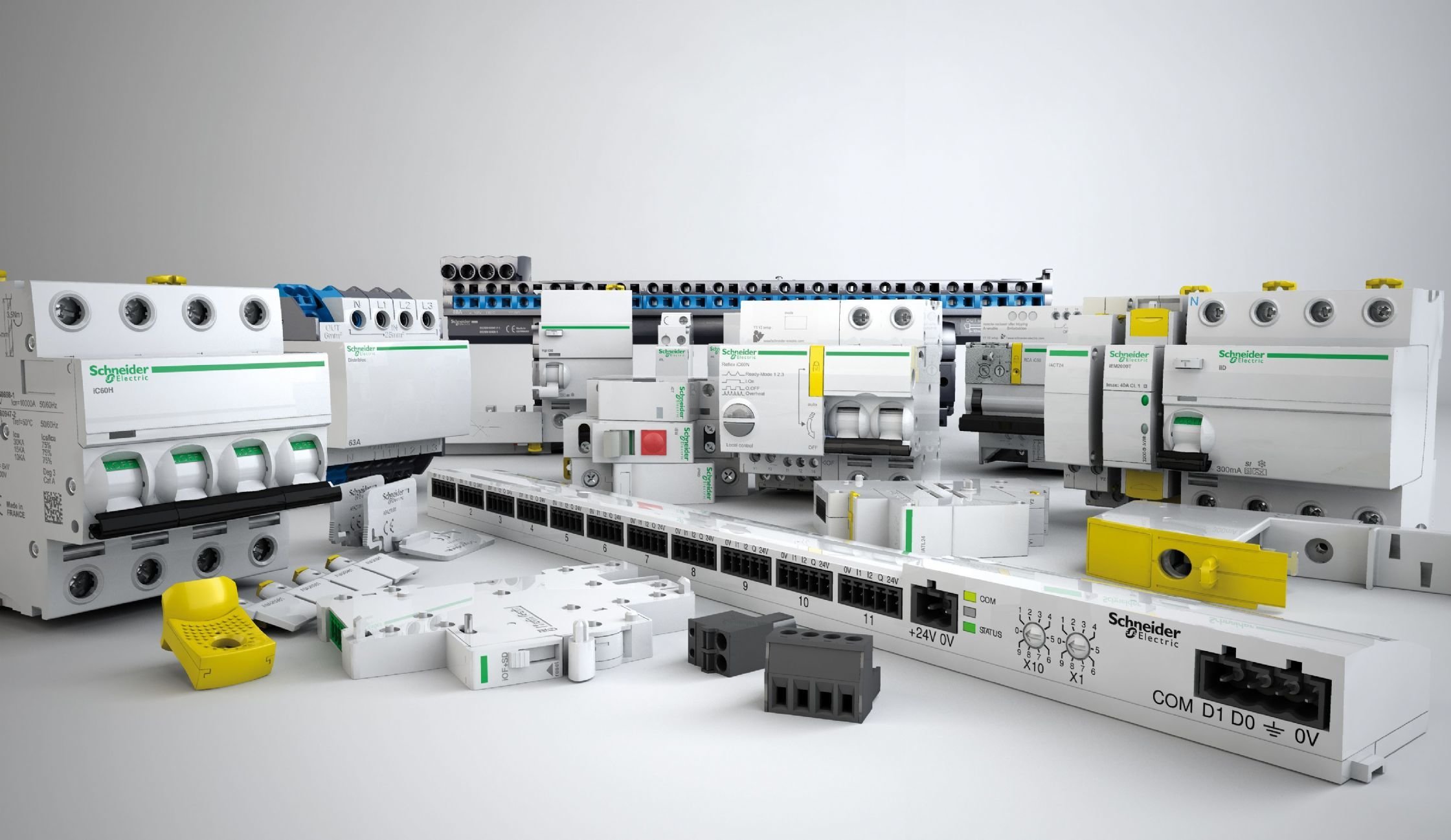

- Circuit Breaker

- Ethernet Interface

- Examples Provided by the Class

- Course Summary

- Review of Key Concepts

- Resources for EMC Problem Solving

Course Instructor

Dr. Todd H. Hubing is a Professor Emeritus of Electrical and Computer Engineering at Clemson University and former Director of the Clemson Vehicular Electronics Laboratory. He has contributed to the development and analysis of hundreds of electronic components and systems and is one of the very few consultants who guarantees that the products he reviews will meet all their EMC requirements on the first test pass. Dr. Hubing has taught EMC classes to hundreds of university students and reached thousands of working engineers and technicians through his EMC short courses and seminars.