Open-Enrollment Course in January 2026

Advanced Design for EMC Compliance (12 hours - $895)

Eight 90-minute sessions, January 26 - February 5, 11:00 am EST (UTC-5)

This course leads students through the process of systematically ensuring that their product designs will meet all applicable EMC requirements. Students will learn to identify and utilize the ground structure, control the flow of high- and low-frequency currents, identify and characterize potential sources and victims of EMI, control bandwidths, ignore structures and coupling paths that do not contribute to EMC problems, and systematically identify and evaluate structures and coupling paths capable of causing a product to be non-compliant. The course is taught live, online in eight 90-minute sessions. Each session starts at 11:00 am EST, Monday, January 26, through Thursday, February 5.

Enrollment is limited, and registration will close when the limit has been reached.

Fundamentals of Electromagnetic Compatibility

Nearly all electronic systems are required to meet electromagnetic compatibility (EMC) requirements before they can be sold or offered for sale. For many automotive, aerospace and industrial systems, electromagnetic compatibility is a product safety issue as well as a product compliance issue. Systems with printed circuit boards that are auto-routed or laid out according to a list of “design rules” do not usually meet electromagnetic compatibility requirements. These systems are likely to require multiple trips to the test lab and expensive "fixes" such as ferrites on cables or extensive shielding.

Product engineers with a basic knowledge of important EMC fundamentals can easily avoid many of the most common design mistakes that result in EMC test failures. This course is designed to introduce these fundamental concepts to circuit designers, board layout professionals, test engineers or anyone with an interest in ensuring that electronic systems meet their EMC requirements. The course stresses the fundamental concepts and tools that electronics engineers can employ to avoid electromagnetic compatibility and signal integrity problems. Students completing the course will be able to make good decisions regarding board layout and system design for EMC. They will also be well prepared for advanced courses in electromagnetic compatibility that require students to have a basic grasp of important fundamental concepts. Course Outline

Advanced Design for EMC Compliance

Electronic products should be designed to meet all electromagnetic compatibility requirements, then tested once to validate the design. A product that fails to meet EMC requirements the first time, and is subsequently redesigned and retested until it passes, will generally be more costly and less reliable than products designed to comply. Designing for EMC compliance is a systematic and cost-effective way to ensure that products won't have problems in the field, as compared to testing and fixing product designs after the first prototype is available.

Designing for EMC compliance is not a matter of following a set of design rules or sealing everything inside a metal enclosure. It is a systematic process of identifying and evaluating all EMC sources, victims and coupling paths within a system, as well as coupling between the system and its environment. Designing for compliance helps to ensure that products meet their cost and development schedule targets.

This course leads students through the process of systematically ensuring that their product designs will meet all applicable EMC requirements. Students will learn to identify and utilize the ground structure, control the flow of high- and low-frequency currents, identify and characterize potential sources and victims of EMI, control bandwidths, ignore structures and coupling paths that do not contribute to EMC problems, and systematically identify and evaluate structures and coupling paths capable of causing a product to be non-compliant. Course Outline

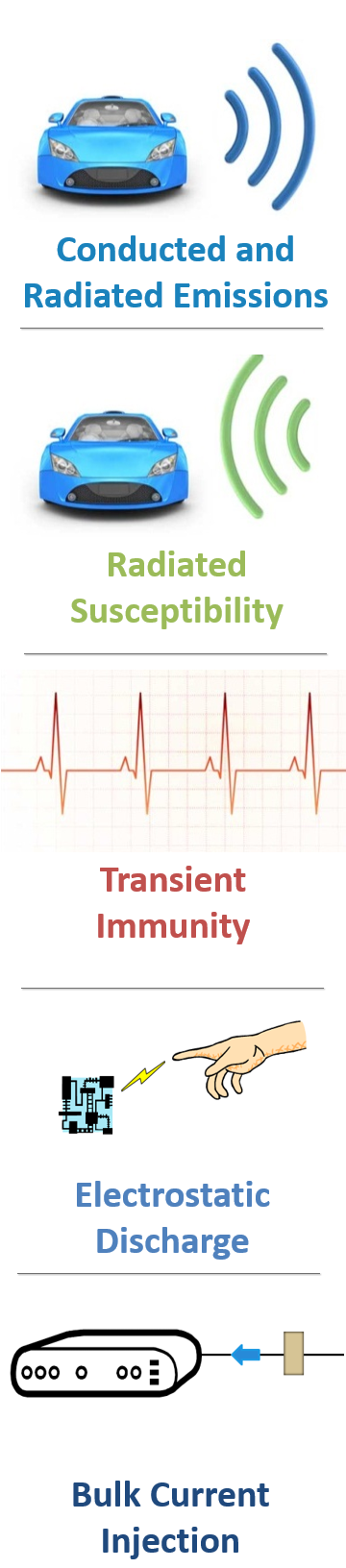

The Physics of Electromagnetic Compatibility Measurements

This course reviews the equipment, test setups and primary coupling mechanisms associated with each of the major electromagnetic compatibility tests. The goal of the course is to provide a basic understanding of the physics involved in order to make better, more meaningful and more repeatable measurements.

The primary EMC tests covered by this course are Conducted and Radiated Emissions, Radiated Immunity, Bulk Current Injection, Electrical Fast Transient testing and Electrostatic Discharge testing. Other EMC tests such as Lightning Immunity, Magnetic Field Emissions and Power Disturbance tests will also be discussed. Commercial, automotive and military EMC test procedures in each of these categories will be reviewed. While the course will refer to industry standard tests, the focus is on general physics, not the specific requirements of any given standard.

For each EMC test, the course reviews the test equipment, test settings and set-up parameters that affect the measurement results. Basic models of the measurements are presented that help test engineers and technicians understand exactly what is being measured. These models illustrate how sometimes seemingly minor decisions related to the test setup can significantly affect the results of a measurement. Course Outline