Fundamentals of Electromagnetic Compatibility

Description

Nearly all electronic systems are required to meet electromagnetic compatibility (EMC) requirements before they can be sold or offered for sale. For many automotive, aerospace and industrial systems, electromagnetic compatibility is a product safety issue as well as a product compliance issue. Systems with printed circuit boards that are auto-routed or laid out according to a list of “design rules” do not usually meet electromagnetic compatibility requirements. These systems are likely to require multiple trips to the test lab and expensive "fixes" such as ferrites on cables or extensive shielding.

Product engineers with a basic knowledge of important EMC fundamentals can easily avoid many of the most common design mistakes that result in EMC test failures. This 12-hour course is designed to introduce these fundamental concepts to circuit designers, board layout professionals, test engineers or anyone with an interest in ensuring that electronic systems meet their EMC requirements. The course stresses the fundamental concepts and tools that electronics engineers can employ to avoid electromagnetic compatibility and signal integrity problems. Students completing the course will be able to make good decisions regarding board layout and system design for EMC. They will also be well prepared for advanced courses in electromagnetic compatibility that require students to have a basic grasp of important fundamental concepts.

Continuing Education Credit: 1.2 CEUs, 12 PDHs

Course Outline

Part 1 - Basic Fundamental Concepts

- Introduction

- Overview of Electromagnetic Compatibility

- Importance of Addressing EMC Issues Early

- Examples of EMC Disasters (and Success Stories)

- Circuit Components and Parasitics

- Resistance, Capacitance and Inductance

- Absolute Capacitance, Self Capacitance and Mutual Capacitance

- Self Inductance, Mutual Inductance, Partial Inductance, Internal and External Inductance

- Component Parasitics

- Rules and Tools for Estimating Parasitic Values

- Coupling Mechanisms

- Common Impedance Coupling

- Electric Field Coupling

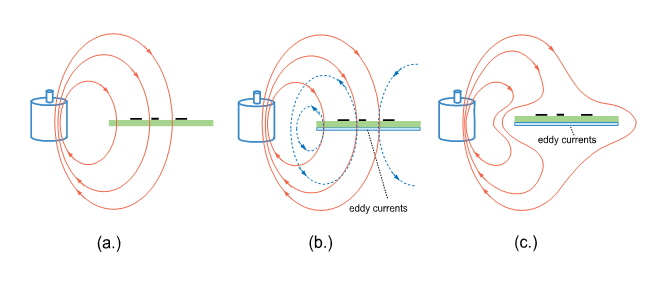

- Magnetic Field Coupling

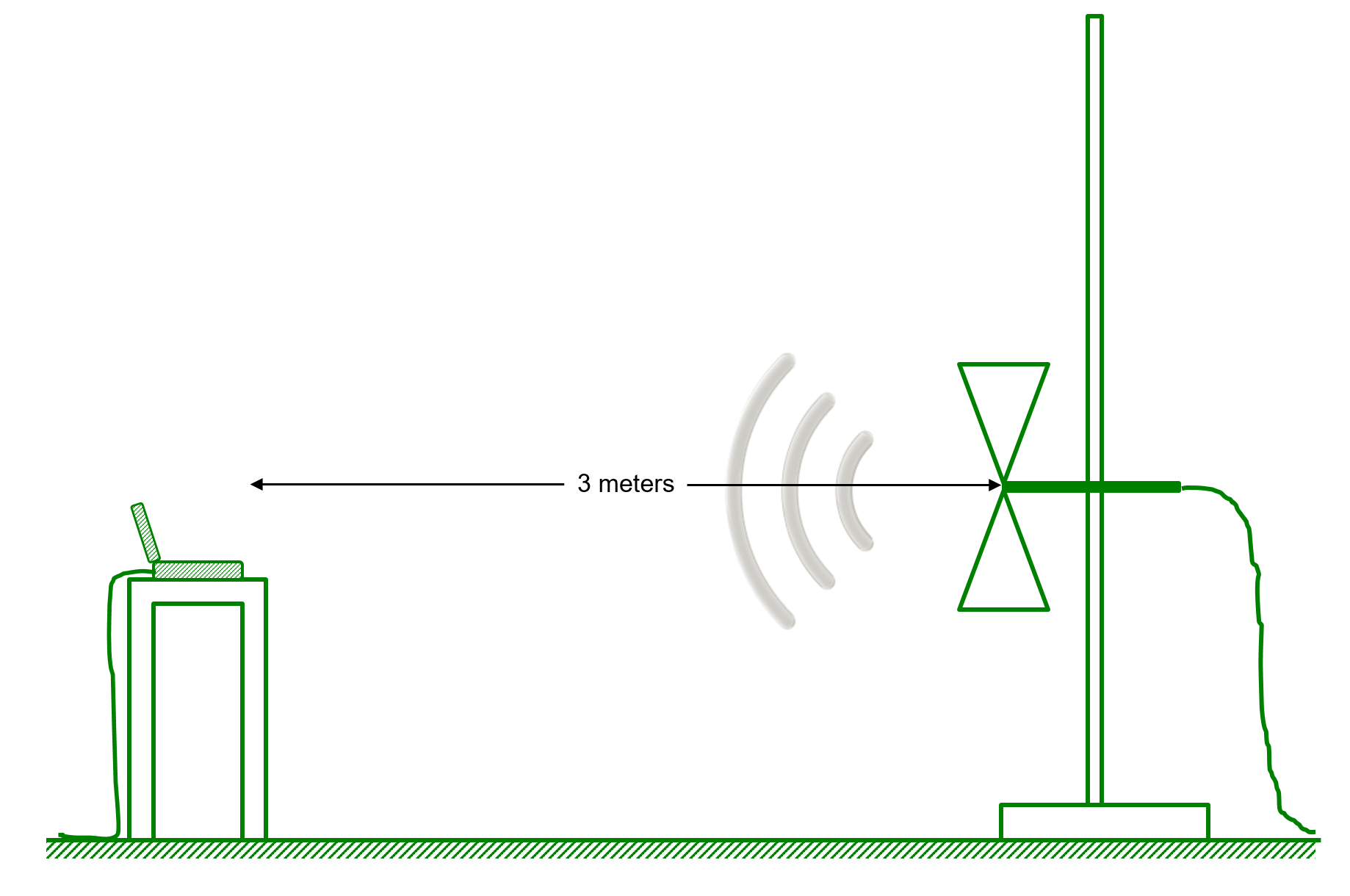

- Electromagnetic Radiation

- Signal Routing and Termination

- Tracing Current Paths / Concept of Least Impedance

- Transition Time Control

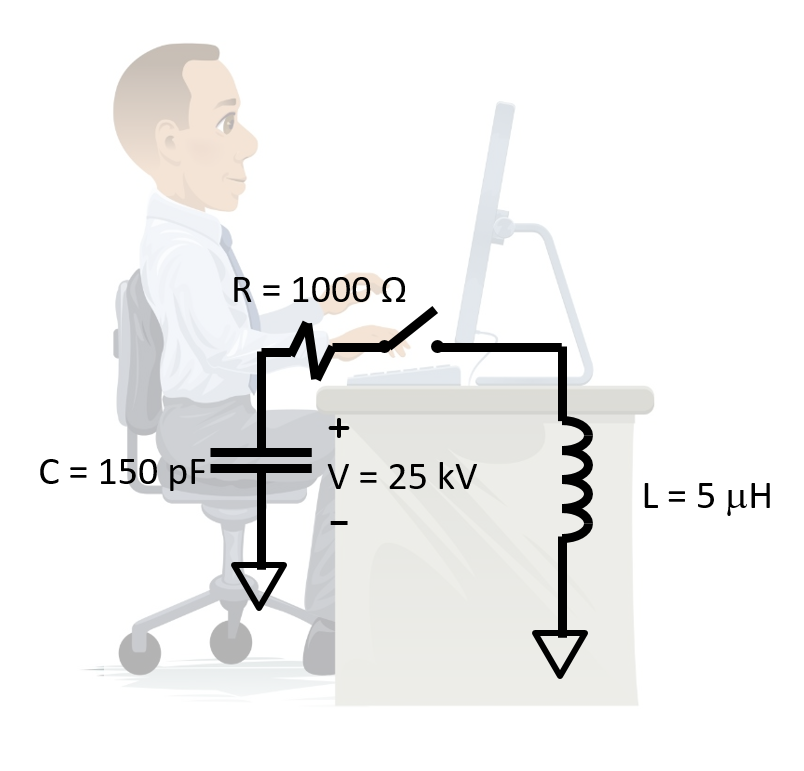

- RLC Circuits

- Transmission Lines

- Single-ended vs. Differential vs. Pseudo-Differential Signals

- Balanced vs. Unbalanced Sources and Channels

- Grounding

- Ground vs. Current Return

- Ground Structures and Grounding Conductors

- Strategies for Mixed-Signal PCB Layout

- Managing Current Return Paths

- Managing Ground

- Design Examples

Part 2 - Applied Fundamentals

- Filtering

- Insertion Loss

- First-Order Low-Pass Filters

- Second-Order Low-Pass Filters

- Component Parasitics

- Shielding

- Electric Field Shielding

- Magnetic Field Shielding

- Shielding to Reduce Radiated Emissions

- Cable Shielding

- DC Power Distribution and Decoupling

- Effective Power Distribution Strategies

- Choosing and Locating Decoupling Capacitors

- Low-Inductance Capacitor Connections

- Isolating PLLs and Other Sensitive Devices

- Identifying the Unintentional Antennas

- Essential Elements of an Antenna

- What Makes a Good Antenna

- What Makes a Poor Antenna

- Noise Sources and Coupling Mechanisms

- Integrated Circuits as Sources of EMI

- Parasitic Oscillations and Unexpected Noise Sources

- Coupling Between Noise Sources and Antennas

- Differential Mode to Common Mode Conversion

- Key System-Level Design Considerations

- For Radiated Emissions Tests

- For Conducted Emissions Tests

- For Radiated Susceptibility

- For ESD and Transient Tests

- Avoiding Common EMC Design Mistakes

- EMC Design Rules (Good, Bad and Awful)

- Ground Partitioning

- Bypassing Your Filters

- Course Summary

- Review of Key Concepts

- EMC Resources for Product Engineers

Course Instructor

Dr. Todd H. Hubing is a Professor Emeritus of Electrical and Computer Engineering at Clemson University and former Director of the Clemson Vehicular Electronics Laboratory. He and his students at Clemson have worked on the development and analysis of a wide variety of electronic products. EMC design rules can vary greatly depending on whether you are designing high-speed computing equipment, low-cost mixed-signal consumer products or high-power industrial controls; but the basic EMC principles are the same in all industries. By applying these principles in an organized manner, it is possible to review a design circuit-by-circuit to guarantee that any particular EMC requirement will be met. This approach is more effective than the blind application of design guidelines and is the primary emphasis of every EMC design class taught by Dr. Hubing.