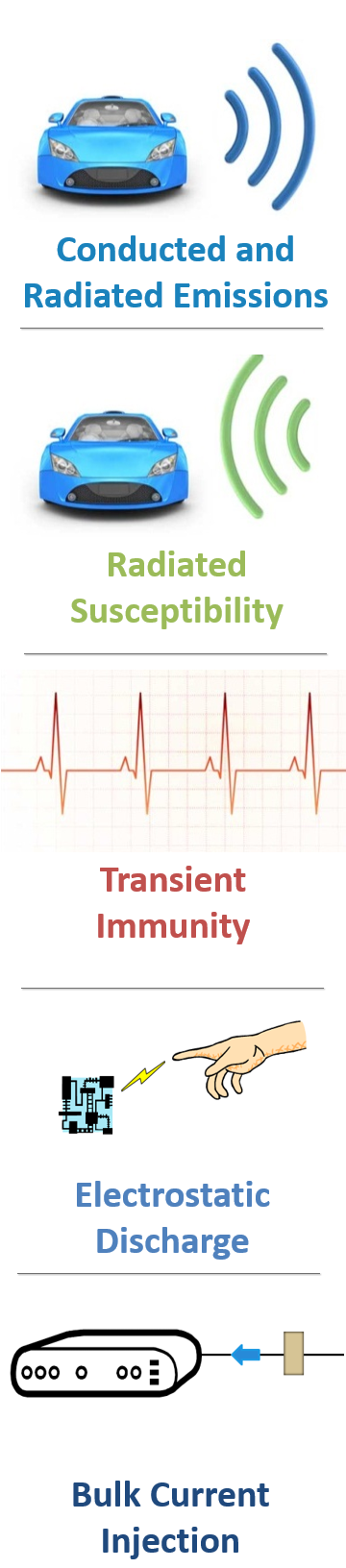

Printed Circuit Board Design for EMC and Signal Integrity

Today's rapid development cycles require products to meet their EMC requirements the first time they come into the lab for testing. Board layout changes and other EMC "fixes" can significantly add to the cost of a product and/or delay its development schedule. First-pass compliance with EMC requirements starts with the circuit board layout. Printed circuit board layout is often the single most important factor affecting the electromagnetic compatibility of electronic systems. Boards that are auto-routed or laid out according to a list of “design rules” do not usually meet electromagnetic compatibility requirements on the first pass; and the products using these boards are more likely to require expensive fixes such as ferrites on cables or shielded enclosures. Taking the time to ensure that components are properly placed, transition times are not left to chance, and traces are optimally routed will generally result in products that meet all electromagnetic compatibility and signal integrity requirements on time and on budget.

Recognizing poor design features early in a product’s development can save a lot of time and expense later on. This course stresses the fundamental concepts and tools that board designers must be familiar with to avoid electromagnetic compatibility and signal integrity problems. Students completing the course will be able to make good decisions regarding component selection, component placement, and trace routing. In addition, students will have the knowledge and tools necessary to design effective power distribution and grounding strategies for both digital and mixed-signal boards. Course Outline

Power Electronics Design for Electromagnetic Compatibility

This course covers fundamental and advanced design concepts related to the design of power electronic circuits for meeting electromagnetic compatibility requirements. In the morning session, basic power electronic circuit topologies and applications are reviewed with a focus on the fundamental properties of these circuits that result in unwanted conducted and radiated emissions. Noise source models are presented and various noise mitigation options are examined. The focus of the afternoon session is on advanced design concepts including grounding strategies, component selection and placement, and methods for maintaining electrical balance. Active noise cancellation techniques applicable in various situations are also presented. Finally, examples of good and bad power circuit designs ranging from low-voltage DC-to-DC converters to 700-volt electric vehicle motor drives are reviewed. Course Outline

The Physics of Electromagnetic Compatibility Measurements

This course reviews the equipment, test set-ups and primary coupling mechanisms associated with each of the major electromagnetic compatibility tests. The goal of the course is to provide a basic understanding of the physics involved in order to make better, more meaningful and more repeatable measurements.

The primary EMC tests covered by this course are Conducted and Radiated Emissions, Radiated Immunity, Bulk Current Injection, Electrical Fast Transient testing and Electrostatic Discharge testing. Other EMC tests such as Lightning Immunity, Magnetic Field Emissions and Power Disturbance tests will also be discussed. Commercial, automotive and military EMC test procedures in each of these categories will be reviewed. While the course will refer to industry standard tests, the focus is on the general physics, not the specific requirements of any given standard.

For each EMC test, the course reviews the test equipment, test settings and set-up parameters that affect the measurement results. Basic models of the measurements are presented that help test engineers and technicians understand exactly what is being measured. These models illustrate how sometimes seemingly minor decisions related to the test set-up can significantly affect the results of a measurement. Course Outline

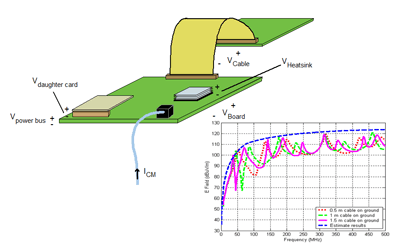

Computer Modeling Tools for Electromagnetic Compatibility

Computer modeling has become an important part of the design process for electronic systems. This course reviews the latest computer modeling tools and techniques available to help engineers design products that comply with electromagnetic compatibility requirements. The course covers electromagnetic modeling codes, circuit solvers, rule checkers, analytical modeling tools, web-based calculators and apps. Plenty of examples demonstrating the application of various modeling tools to real-world EMC design problems are provided. Students completing the course will be aware of the tools available to them and able to make good decisions regarding the tools that are appropriate for their needs. Course Outline